Many US and European firms that beforehand offshored their

industrial operations to cheaper nations equivalent to China are literally relocating

manufacturing once more to their dwelling nations.

This phenomenon, typically known as

nearshoring

or

reshoring,

has taken off massively since 2020 — first, as a consequence of COVID-19; however moreover on account of

rising geopolitical friction with China, the worldwide manufacturing hub. A

Kearney analysis reveals that 96 % of US

CEOs

intend to convey once more their manufacturing to the US, or have already taken steps

to take motion — up from 78 % in 2022.

Nonetheless, merely transferring a producing unit from China or Taiwan to Arizona or

Ohio should not be sufficient for US producers to fulfill the requires and values of US

clients. In a November 2023

survey by

American Compass and YouGov, 42 % of US clients actually really feel that

“manufacturing is important to a healthful, rising, progressive financial system” and

clamor for US-made merchandise.

The unhealthy info is that 62 % need to pay better prices to assist US

manufacturing, fairly than pay additional to combat native climate change (38 %); over

half of US adults surveyed need policymakers to focus on enhancing the US

industrial sector, fairly than bettering the setting.

The survey reveals three competing needs — revitalize left-behind communities,

improve house manufacturing, and combat native climate change — which respondents uncover

it troublesome to juggle and harmonize.

What if Western firms capitalized on the reshoring improvement throughout the US and Europe to

totally rework manufacturing price chains to have the ability to deal with their

shoppers’ three competing aspirations? Producers can receive that Holy Grail of

balancing monetary improvement, social cohesion, and environmental stewardship if

they boldly reinvent their outmoded price chains.

Limitations of worldwide price chains

In proper now’s customer-centric, collaborative and shortly altering financial system, the

standard price chain —

a set of interconnected actions to develop and convey a product to shoppers —

faces 4 most important limitations.

The linear price chain fails to work together creative ‘prosumers’

Producers view shoppers as nothing better than strolling wallets. They see patrons as

passive receivers of the price chain’s output — excluding them from actively

collaborating in R&D, manufacturing and promoting. Nonetheless, empowered by the

net, social media, digital devices equivalent to 3D printing, creative areas such

as FabLabs, and decentralized vitality

applications,

passive patrons are evolving into full of life

“prosumers” — spearheading the

Do-It-Your self (DIY) Maker

movement.

Futurist Alfin Toffler predicted

that this “prosumation” movement will velocity up all through the twenty first century and

blur the highway between manufacturing and consumption, compelling firms to

rethink their engagement with shoppers all by the price chain.

The insular price chain doesn’t favor B2B collaboration

The standard price chain focuses internally. It outlines a sequence of

associated actions carried out by a company using fully its private

property — and folks of its suppliers and companions — to point out an idea proper right into a

closing companies or merchandise for the shopper. From this angle, a mannequin’s

aggressive profit lies in its performance to optimize its private price

chain additional

successfully than rivals.

Inside the interdependent enterprise setting, nonetheless, the concept of aggressive

profit is being modified by cooperative profit. Revolutionary firms try

to collaborate with totally different firms, even rivals, to collectively create new and

larger “blue ocean” market

options which may be

advantageous for all. Because of B2B sharing

platforms,

firms in a number of sectors can proper now combine their R&D, manufacturing and

go-to-market property to co-create higher price for all stakeholders.

The static price chain doesn’t ship agility and resilience

Using lean manufacturing methods equivalent to Six

Sigma

and

Kaizen,

firms have fine-tuned their price chain to achieve effectivity helpful properties. Proper this second,

producers leverage their “lean” price chains to provide and ship their merchandise

cheaper and quicker. Nevertheless these well-oiled, static price chains lack the agility

and

resilience

needed to reply surprising market shifts.

Equally, when cataclysmic events equivalent to pandemics, wars and pure disasters strike,

many firms uncover it

troublesome

to swiftly modify their inflexible price chain processes to forestall

disruptions.

In a VUCA (dangerous, not sure, difficult, and ambiguous) world, firms ought to

collaborate with suppliers and companions to create agile and resilient price

chains

which will reply shortly to supply and demand fluctuations.

The wasteful and difficult price chain is unsustainable

From apparel and automotive to meals and vitality, every commerce price chain —

whether or not or not globally dispersed or nationally built-in — is notoriously wasteful

and unsustainable. As an illustration, from the cotton self-discipline to the shop, a pair of

jeans travels 1.5 events throughout the

planet

— which offers as a lot as 65,000 km and the associated emissions. Inside the US, current

produce travels 1,500

miles from farm

to plate. Spherical 5 % of the

electrical power

generated throughout the US is misplaced in transmission and distribution, which is

sufficient to power all seven Central American nations.

The complexity of commerce price chains makes them wasteful and unsustainable.

Faculty of Illinois researchers studied 9.5 million meals transit

routes throughout the

US. One meals journey follows “corn grown on an Illinois farm to a grain silo

in Iowa, from the place it is transported to feed cows in Kansas. After

processing, the meat merchandise then make their means once more to Illinois and onto the

cupboards of a grocery retailer in Chicago.”

Likewise, to provide a single passenger automotive — which is made up of 20,000

parts

— a carmaker ought to orchestrate a multi-tiered, worldwide price chain of roughly

8,000 suppliers. Sadly, solely 13 % of

firms

have full visibility into their multi-tiered price chain. The additional layers in a

price chain, the higher its Scope 3

emissions

(significantly upstream

ones)

— which account for as a lot as 90

% of

many firms’ complete carbon footprint.

Bottom line: firms ought to stop orchestrating hyper-global price chains which may be

inflexible, closed, and unsustainable. In its place, they need to assemble and facilitate

hyperlocal price networks which may be adaptable and sustainable, and maximize

social affect.

The rise of hyperlocal price(s) networks

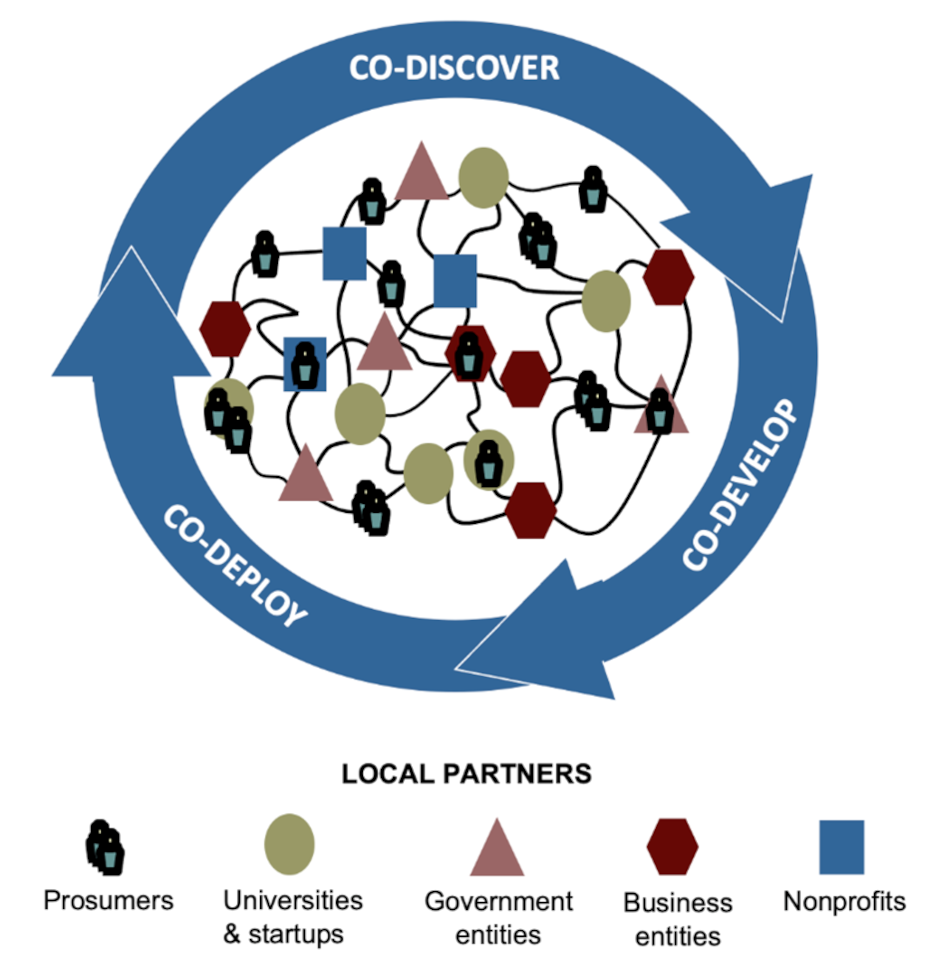

A hyperlocal price group (HYLOVAN) is a dynamic, open ecosystem that

proactively features a numerous set of stakeholders inside a specific area — such

as a metropolis or county — to collaboratively develop personalised choices that

deal with native market and social requirements.

Each phrase in HYLOVAN highlights distinctive choices that make the system way more

impactful than a standard price chain:

“Hyperlocal” refers back to the reality {that a} HYLOVAN can have a geographical

differ that might probably be as restricted as a neighborhood or as in depth as an entire

metropolis — throughout the US, it would not lengthen previous the county diploma.

In order to cut back present chain payments and environmental footprint, a HYLOVAN

primarily obtains its inputs — from raw provides to workforce — from shut by

sources. A giant portion of what it produces — equivalent to companies and merchandise —

is consumed contained in the native area, although some could also be delivered to shut by

communities using eco-friendly transportation methods. Due to this, a HYLOVAN is

intrinsically frugal.

Take Vertical Harvest’s vertical farm in Jackson Hole,

Wyoming: It is three

tales tall and solely takes up 1/10 of an acre, however it is able to develop and

ship 100,000 kilos of current leafy greens year-round to native consuming locations and

groceries. On frequent, Vertical Harvest’s healthful produce solely travels 6 miles

from the farm to the customer — a rather a lot shorter distance than current meals’s

typical 1,500-mile journey throughout the US.

Vertical Harvest minimizes its carbon footprint nevertheless maximizes its social

handprint: 40 % of its employees are individuals with

disabilities.

The group is growing its worthwhile hyperlocal meals manufacturing model

to the state of Maine, the place its hydroponic greenhouse will develop yearly

over 2 million kilos of current

produce

and make use of spherical 50 underserved neighborhood members.

Equally, in early 2023, CarbonCure and

Heirloom — two startups centered on carbon

elimination and utilization, carried out a worthwhile pilot

endeavor

the place they captured CO2 from the air and saved it fully in concrete for

use in native improvement initiatives. All the price chain — the carbon-capture

unit, the concrete batch plant and improvement web sites — was situated end to complete

contained in the San Francisco Bay Area.

“Value(s)” means a HYLOVAN targets to valorize — unleash the whole price of —

bodily, pure, psychological, cultural and social belongings which have been

underused or devalued in a neighborhood area as a consequence of monetary or historic parts.

Moreover, a HYLOVAN promotes optimistic values — equivalent to equity, perception,

sustainability — inside a neighborhood by embodying them.

As an illustration, the French postal service La Poste

teamed up with SUEZ — a primary provider of spherical

environmental suppliers — to rearrange Recygo, a 3 manner partnership to assemble and

recycle office waste. Proper this second, 75,000 postal employees and SUEZ employees collect

65 tons of office waste each

day at over 23,000 web sites all through France. Recygo recycles the waste and creates

socio-economic price regionally. The waste is first sorted at a neighborhood center that

employs economically disadvantaged people after which recycled at certainly one of many 84

regional paper mills

situated all by France.

“Neighborhood” refers again to the resilient and versatile properties of a HYLOVAN,

which — in distinction with a monolithic, linear price chain — can always

adapt and

evolve

to efficiently react to shifts in its setting. A HYLOVAN can velocity up

innovation, lower risks and capitalize on new options swiftly by overtly

sharing knowledge with all members — facilitating fast and setting pleasant

coordination.

A hyperlocal price group engages numerous native stakeholders | Image credit score rating: Navi Radjou

A hyperlocal price group engages numerous native stakeholders | Image credit score rating: Navi Radjou

GRDF — France’s prime pure gasoline distributor — has

established a group of Residing

Labs

rooted deeply inside French territoires (a geographical unit similar to US

counties), with the target of repositioning native residents as the focal point of

the vitality transition. Conceptualized by MIT college students, a Residing

Lab is an open innovation ecosystem

that pulls collectively numerous neighborhood members — residents, entrepreneurs,

firms, non-profits, authorities entities — to collectively create invaluable gadgets

and suppliers that revenue and improve most people welfare.

In each neighborhood, GRDF’s Residing Lab applies agile development processes to

work together native companions to iteratively check out, be taught and deploy disruptive choices

— equivalent to the occasion of inexperienced gasoline and agroecology. These choices are

tailored to maximise sustainable price throughout the native context nevertheless could also be

replicated elsewhere. As an example, by producing biomethane

regionally using pure

waste from agriculture and meals, after which injecting it into GRDF’s distribution

group, communities receive vitality self-sufficiency, lower emissions, enhance

soil properly being, defend water property and generate employment options.

As of proper now, 547 methanization

fashions

are injecting immediately into GRDF’s distribution group. By deploying these

Residing Labs all through France, GRDF is proactively scaling out its private working

model

to permit and lead the decentralized manufacturing of renewable

gases

— which in flip, will velocity up the decarbonatization of native communities. GRDF

initiatives that by 2050, 73 % of the gasoline flowing in France’s distribution

grid might probably be inexperienced gasoline — most of which can be produced

regionally.

US and European producers that want to reshore manufacturing and reindustrialize

their nations need to first revamp their whole price chains. By establishing and

facilitating hyperlocal price networks which may be open, adaptable and deeply

rooted in communities, firms can purchase agility and resilience and maximize

sustainable native affect.

Study additional regarding the frugal financial system:

This textual content has been partially tailor-made from the creator’s upcoming e-book, The

Frugal Financial system: A Info to Establishing a Larger World with

A lot much less

(2024), printed by Wiley and Thinkers50.